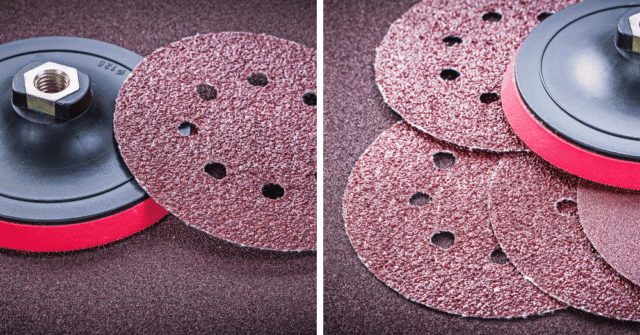

Discs

In both sandpaper and fibre, our discs are manufactured in whatever diameter and backing our customers’ operations require. We can manufacture Velcro discs, pressure sensitive adhesive (PSA) discs, plains and with or without dust extraction configuration.

Sanding disc

The function of a sanding disc is to help us achieve a uniform finish on the materials we are working on. There are different sanding discs, some with finer grits than others, and their use will depend on the level of detail we want to achieve with sanding. When sanding with a sanding disc we can polish, abrade, isolate, as well as refine surfaces of materials such as wood, metals, glass, composites (or composite resins), plastics and varnishes, among others. For each material we have different specialised discs; for example, a sanding disc for wood or a sanding disc for metal will have different characteristics.

How to use a sanding disc?

To achieve more uniformity or variety in our finishes using a sanding disc, we must give several passes with it to the materials we want to polish until we achieve the desired result. For more detailed and neat effects, it is advisable to go from less to more when sanding, using different sanding discs with finer and finer grits. The finer the grit of a sanding disc, the more detailed the final result of the surface we sand with it will be.

60 grit sanding disc

The rougher the surface, the more sanding it needs. This type of sanding disc will help us to even out our surfaces more quickly and extensively. The 60 grit is usually used when we start sanding a surface in a general way, before it requires finer sanding details.

80 grit sanding disc

For more detailed results. It is only recommended for use when our surface requires little or more detailed and fine sanding. Usually this sanding disc is used after having sanded a material in a general and wide way with a less fine grit sanding disc.

Sanding with sanding discs is usually carried out with rotorbital machines that have a vacuum system to protect the health and comfort of the user. There are different ways of using a sanding disc, which is why we have discs such as the drill sanding disc and the emery sanding disc.

Orbital sanding discs

Orbital discs, either velcro or PSA, with perforations and multi-perforations for dust extraction, come in different types of backing such as paper, film, aluminium oxide mineral, ceramic and zirconia, and in different sizes: 3, 4, 5, 6, 12, up to 24 inches.

Orbital, PSA or Velcro sanding discs are designed to handle specific sanding and finishing needs. Applications include material removal, light weld blending and paint preparation of carbon steel or aluminium surfaces.

PSA discs

PSA discs with glue are used especially in the area of a surface that requires preparation for painting and for wooden areas. To leave a good finish, they are resin bonded to a highly durable fabric backing and are used on smooth and velcro backings. They are made to withstand the high friction temperatures they generate when in use and can be removed manually at the end of use. They come in box or roll form and are used in orbitals with dust extraction.

Flap discs

Flap discs have the characteristic of being made up of sheets, flaps or flaps that cover the entire disc evenly, one after the other. They are usually made of fibreglass or plastic, so their consumption is lower and their use does not stain, as they absorb vibrations. They have a plastic backing that is comfortable to use, are highly resistant and very light in weight.